- Case Studies

- Free Coaching Session

Production Plan in Business Plan: A Comprehensive Guide to Success

Last Updated:

February 26, 2024

In any business venture, a solid production plan is crucial for success. A production plan serves as a roadmap that outlines the steps, resources, and strategies required to manufacture products or deliver services efficiently. By carefully crafting a production plan within a business plan, entrepreneurs can ensure optimal utilisation of resources, timely delivery, cost efficiency, and customer satisfaction. In this article, we will delve into the intricacies of creating an effective production plan in a business plan , exploring its key components, strategies, and the importance of aligning it with overall business objectives .

Key Takeaways on Production Plans in Business Planning

- A production plan : a detailed outline that guides efficient product manufacturing or service delivery.

- Importance of a production plan : provides a roadmap for operations, optimises resource utilisation, and aligns with customer demand.

- Key components : demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance.

- Strategies : lean manufacturing, JIT inventory, automation and technology integration, supplier relationship management, and continuous improvement.

- Benefits of a well-executed production plan : improved efficiency, reduced costs, enhanced product quality, and increased profitability.

What is a Production Plan?

A production Seamless Searches plan is a detailed outline that specifies the processes, resources, timelines, and strategies required to convert raw materials into finished goods or deliver services. It serves as a blueprint for the entire production cycle, guiding decision-making and resource allocation. The production plan considers factors such as demand forecasting, capacity planning, inventory management, and quality assurance to ensure efficient operations and optimal customer satisfaction.

Why is a Production Plan Important in a Business Plan?

The inclusion of a production plan in a business plan is vital for several reasons. First and foremost, it provides a clear roadmap for business operations, helping entrepreneurs and managers make informed decisions related to production processes. A well-developed production plan ensures that resources are utilised efficiently, minimising wastage and optimising productivity.

Additionally, a production plan allows businesses to align their production capabilities with customer demand. By forecasting market trends and analysing customer needs, businesses can develop a production plan that caters to current and future demands, thus avoiding overstocking or understocking situations.

Furthermore, a production plan helps businesses enhance their competitive advantage. By implementing strategies such as lean manufacturing and automation, companies can streamline their production processes, reduce costs, improve product quality, and ultimately outperform competitors.

Key Components of a Production Plan

To create an effective production plan, it is crucial to consider several key components. These components work together to ensure efficient operations and successful fulfilment of customer demands. Let's explore each component in detail.

Demand Forecasting

Demand forecasting is a critical aspect of production planning. By analysing historical data, market trends, and customer behaviour, businesses can predict future demand for their products or services. Accurate demand forecasting allows companies to optimise inventory levels, plan production capacity, and ensure timely delivery to customers.

One approach to demand forecasting is quantitative analysis, which involves analysing historical sales data to identify patterns and make predictions. Another approach is qualitative analysis, which incorporates market research, customer surveys, and expert opinions to gauge demand fluctuations. By combining both methods, businesses can develop a robust demand forecast, minimising the risk of underproduction or overproduction. Utilising a free notion template for demand forecasting can further streamline this process, allowing businesses to organise and analyse both quantitative and qualitative data efficiently in one centralised location.

Capacity Planning

Capacity planning involves determining the optimal production capacity required to meet projected demand. This includes assessing the production capabilities of existing resources, such as machinery, equipment, and labour, and identifying any gaps that need to be addressed. By conducting a thorough capacity analysis, businesses can ensure that their production capacity aligns with customer demand, avoiding bottlenecks or excess capacity.

An effective capacity plan takes into account factors such as production cycle times, labour availability, equipment maintenance, and production lead times. It helps businesses allocate resources efficiently, minimise production delays, and maintain a consistent level of output to meet customer expectations.

Inventory Management

Efficient inventory management is crucial for a successful production plan. It involves balancing the cost of holding inventory with the risk of stockouts. By maintaining optimal inventory levels, businesses can reduce carrying costs while ensuring that sufficient stock is available to fulfil customer orders.

Inventory management techniques, such as the Economic Order Quantity (EOQ) model and Just-in-Time (JIT) inventory system, help businesses strike the right balance between inventory investment and customer demand. These methods consider factors such as order frequency, lead time, and carrying costs to optimise inventory levels and minimise the risk of excess or insufficient stock.

Resource Allocation

Resource allocation plays a pivotal role in a production plan. It involves assigning available resources, such as labour, materials, and equipment, to specific production tasks or projects. Effective resource allocation ensures that resources are utilised optimally, avoiding underutilisation or overutilisation.

To allocate resources efficiently, businesses must consider factors such as skill requirements, resource availability, project timelines, and cost constraints. By conducting a thorough resource analysis and implementing resource allocation strategies, businesses can streamline production processes, minimise bottlenecks, and maximise productivity.

Quality Assurance

Maintaining high-quality standards is essential for any production plan. Quality assurance involves implementing measures to monitor and control the quality of products or services throughout the production process. By adhering to quality standards and conducting regular inspections, businesses can minimise defects, ensure customer satisfaction, and build a positive brand reputation.

Quality assurance techniques, such as Total Quality Management (TQM) and Six Sigma , help businesses identify and rectify any quality-related issues. These methodologies involve continuous monitoring, process improvement, and employee training to enhance product quality and overall operational efficiency.

In addition to the core components of a production plan, it's also important for businesses to consider the broader aspects of their business strategy, including marketing and advertising. Understanding the costs and returns of different marketing approaches is crucial for comprehensive business planning. For instance, direct response advertising costs can vary significantly, but they offer the advantage of measurable responses from potential customers. This type of advertising can be a valuable strategy for businesses looking to directly engage with their target audience and track the effectiveness of their marketing efforts.

Strategies for Developing an Effective Production Plan

Developing an effective production plan requires implementing various strategies and best practices. By incorporating these strategies into the production planning process, businesses can optimise operations and drive success. Let's explore some key strategies in detail.

Lean Manufacturing

Lean manufacturing is a systematic Seamless Searches approach aimed at eliminating waste and improving efficiency in production processes. It emphasises the concept of continuous improvement and focuses on creating value for the customer while minimising non-value-added activities.

By adopting lean manufacturing principles, such as just-in-time production, standardised work processes, and visual management, businesses can streamline operations, reduce lead times, and eliminate unnecessary costs. Lean manufacturing not only improves productivity but also enhances product quality and customer satisfaction.

Just-in-Time (JIT) Inventory

Just-in-Time (JIT) inventory is a strategy that aims to minimise inventory levels by receiving goods or materials just when they are needed for production. This strategy eliminates the need for excess inventory storage, reducing carrying costs and the risk of obsolete inventory.

By implementing a JIT inventory system, businesses can optimise cash flow, reduce storage space requirements, and improve overall supply chain efficiency. However, it requires robust coordination with suppliers, accurate demand forecasting, and efficient logistics management to ensure timely delivery of materials.

Automation and Technology Integration

Automation and technology integration play a crucial role in modern production planning. By leveraging technology, businesses can streamline processes, enhance productivity, and reduce human error. Automation can be implemented in various aspects of production, including material handling, assembly, testing, and quality control.

Continuous Improvement

Continuous improvement is a fundamental principle of effective production planning. It involves regularly evaluating production processes, identifying areas for improvement, and implementing changes to enhance efficiency and quality.

By fostering a culture of continuous improvement, businesses can drive innovation, optimise resource utilisation, and stay ahead of competitors. Techniques such as Kaizen, Six Sigma, and value stream mapping can help businesses identify inefficiencies, eliminate waste, and streamline production workflows.

Frequently Asked Questions (FAQs)

What is the role of a production plan in business planning.

A1: A production plan plays a crucial role in business planning by providing a roadmap for efficient production processes. It helps align production capabilities with customer demand, optimise resource utilisation, and ensure timely delivery of products or services.

How does a production plan affect overall business profitability?

A2: A well-developed production plan can significantly impact business profitability. By optimising production processes, reducing costs, and enhancing product quality, businesses can improve their profit margins and gain a competitive edge in the market.

What are the common challenges faced in production planning?

A3: Production planning can present various challenges, such as inaccurate demand forecasting, capacity constraints, supply chain disruptions, and quality control issues. Overcoming these challenges requires robust planning, effective communication, and the implementation of appropriate strategies and technologies.

What is the difference between short-term and long-term production planning?

A4: Short-term production planning focuses on immediate production requirements, such as daily or weekly schedules. Long-term production planning, on the other hand, involves strategic decisions related to capacity expansion, technology investments, and market expansion, spanning months or even years.

How can a production plan be adjusted to accommodate changes in demand?

A5: To accommodate changes in demand, businesses can adopt flexible production strategies such as agile manufacturing or dynamic scheduling. These approaches allow for quick adjustments to production levels, resource allocation, and inventory management based on fluctuating customer demand.

In conclusion, a well-crafted production plan is essential for business success. By incorporating a production plan into a comprehensive business plan, entrepreneurs can optimise resource utilisation, meet customer demands, enhance product quality, and drive profitability. Through effective demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance, businesses can streamline production processes and gain a competitive edge in the market.

Related Articles:

Client Success!! Watch THIS >>>

Client Success - Case Study

© 2016 - 2024 Robin Waite. All rights reserved.

What Is Production Planning & Why Is It Important?

Business success often hinges on making the products that customers want in a timely and cost-effective way. Production planning helps companies achieve those goals. It maps out all the processes, resources and steps involved in production, from forecasting demand to determining the raw materials, labor and equipment needed. Production planning helps companies build realistic production schedules, ensure production processes run smoothly and efficiently, and adjust operations when problems occur.

What Is a Production Plan?

A production plan describes in detail how a company’s products and services will be manufactured. It spells out the production targets, required resources, processes and overall schedule. The plan also maps all of the operational steps involved and their dependencies. The goal is to design the most efficient way to make and deliver the company’s products at the desired level of quality. A well-designed production plan can help companies increase output and save money by developing a smoother workflow and reducing waste.

What Is Production Planning?

Production planning involves developing a comprehensive strategy for making the company’s products and services. Initially adopted by large manufacturers, production planning has since become more popular among small and midsize businesses in multiple industries — largely because technology has made it easier to plan and track production processes with less effort. Production planning covers many different aspects of production, from forecasting demand to determining the raw materials, workforce, equipment and steps needed to make the company’s products.

Production Planning vs. Production Scheduling

While production planning provides an overview of what the company plans to do, production scheduling creates a more detailed view of exactly how the company will do it. The production schedule describes when each step in the production plan will occur, as well as the workers, machinery and other specific resources assigned to the job. Production scheduling can be extremely complex, especially when there are many interdependent production steps and the company is making multiple products simultaneously. Production scheduling software (opens in new tab) can help businesses create complex schedules, monitor progress in real time and quickly make adjustments when necessary.

Key Takeaways

- Production planning describes in detail how a company’s products and services will be manufactured.

- A production plan defines the production targets, required resources and overall schedule, together with all the steps involved in production and their dependencies.

- A well-designed production plan helps companies deliver products on time, reduce costs and respond to problems.

- Technology has made it easier for small and midsize companies in multiple industries to use production planning to optimize operations.

Product Planning Explained

Production planning is a broad discipline that involves much more than a focus on manufacturing process efficiency. It is intertwined with nearly every other aspect of the business, including finance, sales, inventory and human resources. Production planning activities include demand forecasting to determine the right mix of products to meet customer needs, as well as selecting the optimal approach to building those products. Production planning also assesses the resources needed to meet production goals and lays out in detail all the operations in the production process. Production plans must include the flexibility to make operational adjustments when problems occur — such as machine breakdowns, staffing shortages and supply-chain problems.

Why Is Production Planning Important?

A well-constructed production plan can help to boost revenue, profit and customer satisfaction, while a poorly designed plan can cause production problems and perhaps even sink the company. Specific benefits of production planning include:

- Knowledge. A production plan provides a framework for understanding the resources and production steps required to meet customer needs. It also helps companies understand the potential problems that may occur during production and how to mitigate them.

- Efficiency. Detailed production planning reduces bottlenecks and helps minimize costs. It also helps ensure the high quality of a product, and it keeps expenses on budget.

- Customer satisfaction. Production planning helps ensure that the company can make and deliver products to customers on time, leading to higher customer satisfaction and a greater likelihood of repeat business.

Types of Production Planning

The design of a product plan depends on the production method that the company uses, as well as other factors, such as product type, equipment capabilities and order size. Here are three of the main types of production planning:

Batch production planning.

Refers to manufacturing identical items in groups rather than one at a time or in a continuous process. For some businesses, batch production can greatly increase efficiency. A bakery creating items for sale the next day might first make a batch of chocolate chip cookies, then move on to oatmeal raisin cookies followed by loaves of semolina bread. A clothing manufacturer making goods for the summer might first set up its cutting and sewing machines to make 500 navy-blue T-shirts, then switch to red fabric and thread to make 400 tank tops. A good production plan for batch processing should look out for potential bottlenecks or delays when switching between batches.

Job- or project-based planning.

Used by many small- and medium-sized businesses, job production planning focuses on the creation of a single item by one person or team. Job-based planning is typically used where the specificity of each client’s requirements means it is difficult to make products in bulk. Many construction businesses use this method. Makers of custom jewelry and dresses are other examples of businesses that may use job production planning.

Flow production planning.

In flow production, also known as continuous production, standardized items are continuously mass-produced on an assembly line. Large manufacturers use this method to create a constant stream of finished goods. During production, each item should move seamlessly from one step along the assembly line to the next. Flow production is most effective at reducing costs and delays when there’s steady demand for the company’s products. Manufacturers can then readily determine their needs for equipment, materials and labor at each stage along the assembly line to help streamline production and avoid delays. The automotive industry and makers of canned foods and drinks are among the companies that use this method.

5 Steps to Make a Production Plan

Production planning is a robust undertaking that starts with forecasting and includes process design and monitoring. Here are five typical production planning steps:

Forecast product demand.

Estimate how much of each product you’ll need to produce over a designated period. Historical data can help with forecasting, but you’ll also need to pay attention to other factors that can affect demand, such as market trends and the economic situation for your customer base. Demand planning software can help companies make more informed decisions about the right amount of product needed to meet demand.

Map out production steps and options.

This step determines the processes, steps and resources needed to produce the required output. At this stage, the company may also examine different options for achieving its production goals, such as outsourcing some stages. The production mapping identifies which steps are interdependent and which can be performed simultaneously. Let’s say the job is to produce 1,000 children’s bicycles. Manufacturing the bicycle frames consists of a series of steps that must happen in sequence — cutting metal tubes, welding and painting — while other activities like assembling wheels can occur in parallel. Do you have all the right equipment? What happens if a machine breaks down? Are your suppliers able to meet your demand?

Choose a plan and schedule production.

Select a production plan after comparing the cost, time required and risks for each option. Sharing the selected plan with all necessary stakeholders typically helps assure a smoother production process since all the stakeholders are aware of what’s needed. Create a detailed production schedule that lays out in detail how the company will execute the plan, including the resources and timing for each step.

Monitor and control.

Once production has begun, you’ll need to track performance and continually compare it against the targets described in the production plan. Careful monitoring helps the company to detect any issues as soon as they pop up, so they can be quickly addressed.

Adjust accordingly.

It’s almost inevitable that production will be affected by events that you can’t plan for or predict. Those events can include changes to client specifications, supply chain lags, equipment failures and worker illness. You may also see ways to improve the production plan after seeing it in action for a while. So it’s vital to keep production plans flexible enough to allow for adjustment when needed. Football coaches often make adjustments to their game strategy at halftime — and the same holds true for production planning.

3 Common Product Planning Mistakes

Being aware of potential pitfalls ahead of time can help companies avoid or mitigate problems once production has started. Here are three of the most common production planning mistakes.

Not anticipating hiccups along the way.

In any complex production process, plans can go awry. Production planning should therefore include risk management strategies, including backup plans companies can rely on in the event of problems. Failing to do so can result in serious problems. For example, if a machine breaks on the line and you didn’t budget for repairs and workforce overtime, the issue may strain the company’s financial resources.

Keeping your distance.

Though production management software can provide real-time visibility into a company’s production status, it’s a good idea to supplement that information with in-person visits to the production line. Those visits can provide valuable insights into how production works in practice — insights that you might not gain if you’re stuck behind a desk.

Failing to maintain equipment.

There’s a tradition in football that the quarterback buys presents for his offensive linemen at the end of each season. Why? Because they protect him and enable him to do his job. Your manufacturing equipment is your company’s offensive line, so don’t neglect it. Tracking usage and paying for regular preventive maintenance helps ensure that your machines can keep your business functioning.

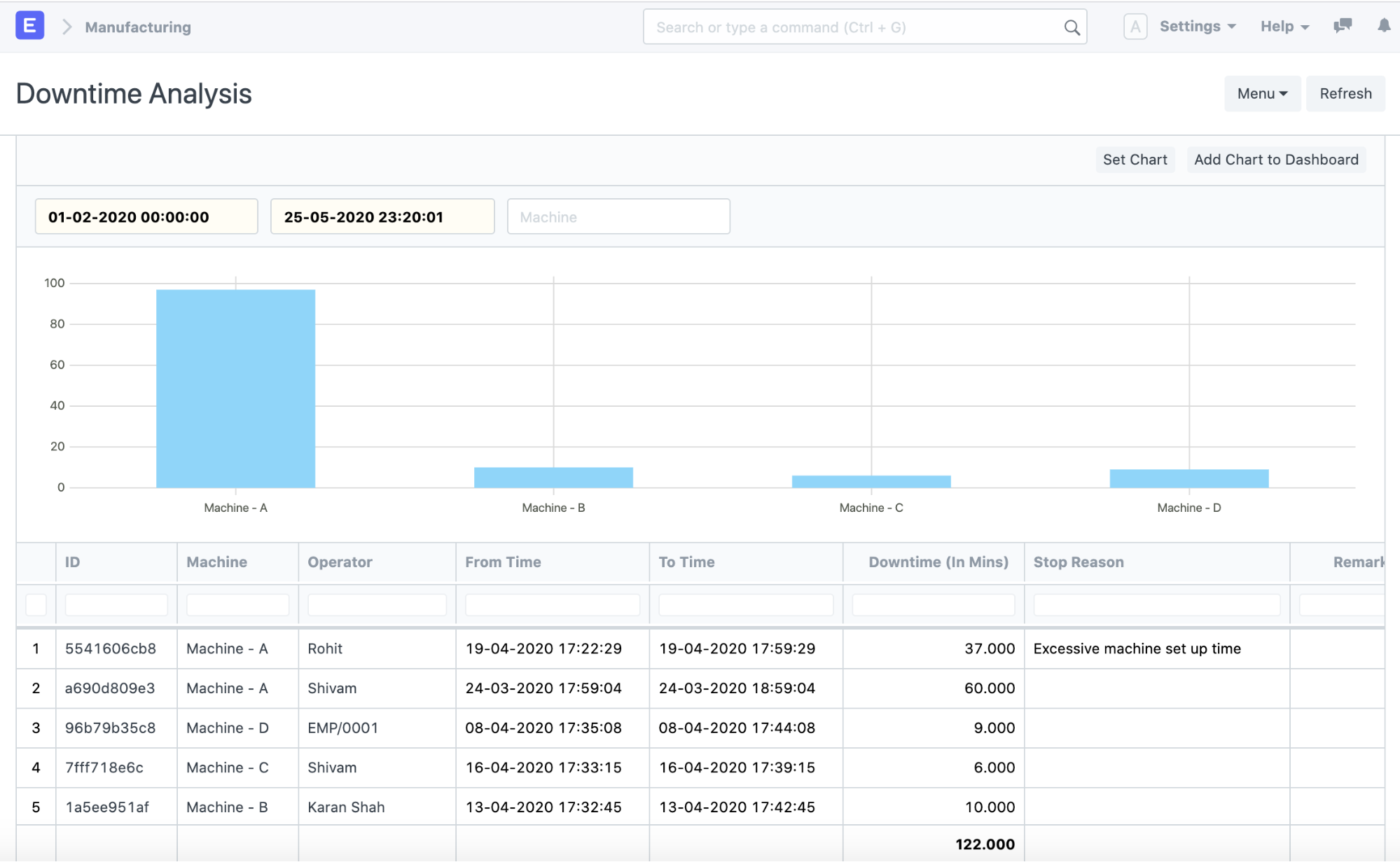

Production Planning KPIs

Key performance indicators (KPIs) are important metrics that help companies track the health of their production processes. By monitoring KPIs and comparing them to target values defined in production plans, businesses can determine whether production is on track and pinpoint problems that need to be addressed. Typical production KPIs include:

This key efficiency metric tracks the percentage of time that production is not occurring during scheduled operating hours. Causes include machine breakdowns, tool adjustments and accidents. Some downtime may be necessary for functions such as machine maintenance, but generally, the less downtime the better.

Setup time.

Also referred to as changeover time, this is the amount of time it takes to switch between jobs. Setup time impacts overall productivity because production is halted during these periods. Production schedules should consider how much time and effort it takes to reconfigure production for each job, including changes to the equipment, raw materials and workforce. Designing production schedules to minimize changeover time can increase efficiency.

Production rate.

In a manufacturing environment, this is typically measured as the number of units produced during a specific period. Comparing the actual production rate for each process with the planned rate can help businesses identify strengths and weaknesses and begin to address problems.

Overall equipment effectiveness (OEE).

This is a measure of overall manufacturing productivity that accounts for quality, performance and availability. The formula for OEE is:

OEE = Quality x performance x availability

Quality is typically measured as the percentage of parts that meet quality standards. Performance is how fast a process is running compared to its maximum speed, which is expressed as a percentage. Availability is the percentage of uptime during a company’s scheduled operating hours. Increasing OEE can be achieved by lowering downtime, reducing waste and maintaining a high production rate.

Rejection rate.

This is the number or percentage of products that failed to pass quality checks. Depending on the nature of the product and the problem, it may be possible to salvage some rejected items by reworking them, while others may need to be scrapped.

On-time orders.

Production delays can be costly both in terms of money and reputation. Generating products on schedule means you’re less likely to need costly expedited shipping or other emergency measures to meet deadlines. And delivering orders on time helps keep customers happy, which means they’re more likely to keep doing business with your company.

Production Planning Tools

Businesses rely on a variety of tools to build production plans and track progress, ranging from visualization tools to sophisticated software that automates many of the steps involved. Typical tools include:

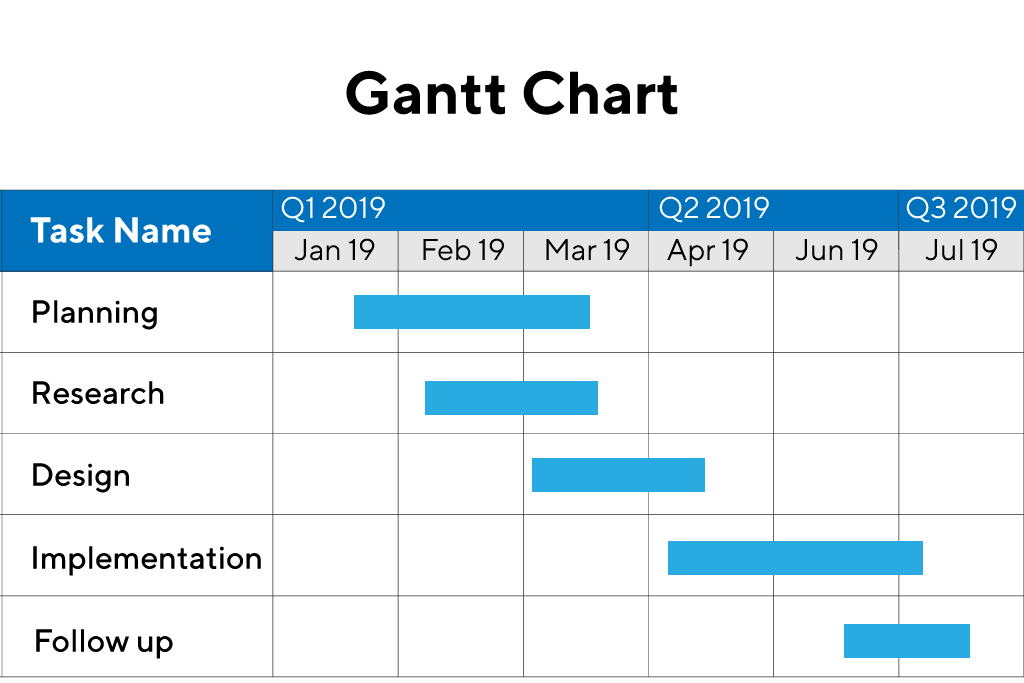

Gantt charts.

A Gantt chart is a detailed visual timeline of all the tasks scheduled for a particular job. More than 100 years since its invention by mechanical engineer Henry Laurence Gantt, this chart remains integral to manufacturing and many other industries. Production planning involves coordinating and scheduling many tasks , and the Gantt chart visually represents when each task will take place and how long it will last. Manually creating and updating Gantt charts to reflect complex, ever-changing production schedules can be a time-consuming and error-prone job, however.

Spreadsheets.

Small companies sometimes start out by tracking simple production plans using spreadsheets. However, for most companies, the inherent complexity of production planning quickly outstrips the capabilities of spreadsheet software.

Production planning software.

Production planning involves a wide range of activities, including forecasting, managing the supply chain, tracking inventory and scheduling jobs. Those activities require information from across the company and beyond. Production planning information is integral to business operations and is used by other groups within the company, including finance. That’s a key reason many companies use enterprise resource planning (ERP) application suites that include production planning software and provide a single solution for managing the entire business.

Manage and Optimize Production With NetSuite

NetSuite cloud-based production management software helps companies maximize manufacturing productivity and minimize cost. NetSuite provides real-time visibility into each aspect of the production process, from inventory tracking and monitoring the production floor to fulfilling orders. Production scheduling capabilities let businesses create and update complex real-time production schedules with minimal effort. Because NetSuite production management software is part of an integrated suite of ERP applications , businesses can share production progress with the entire organization and link production processes to financial reports, inventory management and order management.

Production planning is an important function that can boost profitability and customer satisfaction as well as efficiency. It helps companies match output to demand, optimize production processes and determine how to overcome production problems.

Award Winning Cloud Inventory

Production Planning FAQs

What are the 5 steps in production planning.

Here are five typical steps in the production planning process:

- Forecast the short- and long-term demand for your product.

- Map out the various options and processes for manufacturing these goods

- Choose the option that checks as many boxes as possible, and develop a production schedule.

- Monitor production against the plan.

- Adjust the plan where needed. In other words, if it’s broken, fix it.

What are the 3 activities of production planning?

Production planning activities can be divided into three main areas: Develop a production process and strategy; gather the resources needed, from raw materials to machinery and personnel; and select and train the necessary people.

What are the types of production planning?

Three of the main types of production planning are batch planning, job planning and flow or continuous planning . The choice depends on your resources as well as the nature of the product. Batch planning makes the same item in bulk before moving on to another item. Job planning, also called project-based planning, focuses more on custom design and single-item production. Flow production involves a steady stream of mass-produced items moving along the line.

What is the role of production planning?

Production planning is critical to ensure the production process runs smoothly and efficiently and delivers products on time. Planning allows a business to make certain that all necessary preparation is completed before starting production.

Inventory Management

What Is Perishable Inventory? Strategies, Tracking & Free Template

Inventory management is a challenge faced by any business selling a product, but the challenge is particularly acute for businesses dealing in products that expire or quickly lose value over time. By giving special attention…

Trending Articles

Learn How NetSuite Can Streamline Your Business

NetSuite has packaged the experience gained from tens of thousands of worldwide deployments over two decades into a set of leading practices that pave a clear path to success and are proven to deliver rapid business value. With NetSuite, you go live in a predictable timeframe — smart, stepped implementations begin with sales and span the entire customer lifecycle, so there’s continuity from sales to services to support.

Before you go...

Discover the products that 37,000+ customers depend on to fuel their growth.

Before you go. Talk with our team or check out these resources.

Want to set up a chat later? Let us do the lifting.

NetSuite ERP

Explore what NetSuite ERP can do for you.

Business Guide

Complete Guide to Cloud ERP Implementation

- Contact sales

Start free trial

Production Planning 101: Making a Production Plan (Example Included)

As the creation of products and services has become more extensive and varied, the manufacturing industry has become more competitive. There are many things to keep an eye on such as material requirements planning, supply chain management and inventory control. Operations continue to become more complex, meaning manufacturing companies require more thorough production planning.

A production plan is the best way to guarantee you deliver high-quality products or services as efficiently as possible.

What Is Production Planning?

Production planning is the process of deciding how a product or service will be manufactured before the manufacturing process begins. In other words, it’s how you plan to manage your supply chain, raw materials, employees and the physical space where the manufacturing process occurs.

Production planning is important for manufacturers as it affects other important aspects of their business such as:

- Supply chain management

- Production scheduling

- Material requirements planning

- Production lead time

- Capacity planning

ProjectManager is project management software that helps manufacturers cover every aspect of production planning. Plan with Gantt charts, execute with kanban boards and manage resources along the way. No other software offers sophisticated project and resource management features in one intuitive package. Get started today for free.

Why Is Production Planning Important?

If a manufacturing operation wishes to expand, that evolution demands careful production planning and scheduling. Someone must take on the responsibility of managing resources and deciding how they’ll be allocated. This process is a big part of capacity planning —how much can be made in a certain period, with the available resources?

Without production planning, it’s easy to use too much of a resource for one product and not leave enough for another, or fail to schedule your resources properly, which results in delays that affect your overall production management process. It’s just as easy to let resources go to waste. These issues indicate a lack of efficiency in your production planning process.

Production planning is the best way to ensure resources are used appropriately, products and services are high-quality and nothing goes over budget . In most organizations, a production manager manages the production planning process.

What Does a Production Planner Do?

A production planner is a team leader who oversees the production planning process, which defines how an organization will approach major areas of production management such as production scheduling, resource capacity planning, production control and production budgeting to manufacture products.

To better understand what a production planner does and the importance of this role in any manufacturing organization, let’s dive into each of the steps of the production planning process.

10 Steps of the Production Planning Process

The production planning process consists of an organization’s actions to make a production strategy that allows it to manufacture products most efficiently and profitably. Here are 10 key steps you should follow when planning your production process.

1. Use Production Forecasting Methods for Estimating Customer Demand

The first step of the production planning process is to forecast the customer demand for your product for a future period like a year or a quarter. To do so, manufacturers rely on quantitative and qualitative techniques such as Delphi method, historical analogy method, moving average method and the analysis of business data and sales forecasts.

This process is known as demand planning , which helps manufacturers be better prepared to meet the demand for their products and manufacture the right quantity so they can minimize production and operational costs.

2. Gauge Your Production Capacity

The term production capacity refers to the maximum quantity of product a manufacturing company can produce based on its available production resources such as raw materials, labor, equipment and machinery.

Once you better understand the customer demand for your product, you’ll need to gauge the total quantity of product that needs to be manufactured and then evaluate if your production capacity is sufficient.

3. Map Out the Shop Floor Layout

Now think about the steps of the production process itself. Outline the production tasks that must be executed to transform raw materials, parts and components into a final product and the physical route that those elements will follow to move across the shop floor. This will allow you to pick a production floor layout that minimizes the time and effort required from your employees.

4. Make a Production Budget to Find the Optimal Production Volume

The next challenge in the production planning process is determining the exact number of units to manufacture to keep up with customer demand and maintain your desired stock levels.

This requires a production budget , a document used to calculate the number of units that should be produced by a company to meet the customer demand for a period such as a month, quarter or even a year.

Creating a production budget involves assessing the current product inventory, the production capacity, sales forecasts and the ending inventory that should remain at the end of the period. Once you analyze these variables and use the production budgeting formula, you’ll know the required production level for a given time.

5. Choose a Production Costing Technique

Choose a costing method for your production process such as activity-based costing, process costing, job costing or simply standard costing. Each has its pros and cons depending on your organization’s particular characteristics.

6. Create a Production Schedule

Now it’s time to make a production schedule that allows your organization to create a stock inventory, deliver products to distribution channels, fulfill customer orders and meet the obligations of any manufacturing contracts the organization has in place for the production timeline you’re planning for.

Get your free

- Production Schedule Template

Use this free Production Schedule Template for Excel to manage your projects better.

7. Establish a Production Control System

Next, it’s important to establish standard operating procedures and key performance indicators and use a variety of production control tools to create a system that allows you to track the production process to ensure your products meet quality standards and are manufactured on time and under budget.

8. Set Production Reporting Guidelines

After you’ve decided what KPIs will be used to monitor the efficiency of your production process, you’ll need to determine what types of reports will be used to communicate these metrics with stakeholders and the frequency in which they’ll be produced.

The documentation from each of these production planning stages, such as the production budget and production schedule are gathered in a larger document called the production plan.

What Is a Production Plan?

A production plan is a document that describes how production processes will be executed, and it’s the outcome of the production planning process. It describes the human resources, raw materials and equipment needed and the production schedule that will be followed.

The person responsible for production planning must also be very familiar with the operation’s inner workings, project resources and the products/services they produce. This usually entails collaborating with people on the floor, in the field or in different departments to create products and deliver services.

Production Plan Example

The best way to illustrate this process is through an example. When you set out to create a production plan, make sure to follow these steps to make it as robust as possible.

Sales Forecast

Making a sales forecast greatly helps you decide which product planning method is best for your operation given your production capacity. You’ll need to use diverse sales forecasting techniques to better understand what will be the future demand for your product. From here, you can estimate which resources are required and how they’ll be used in the manufacturing process to begin the production capacity planning process.

Inventory Management Plan

Accessing inventory is about more than simply taking stock: you should make an inventory management plan for your production inventory and work-in-progress inventory so that you don’t experience shortages that might halt production or let things go to waste. For this step, focus on the inventory control and inventory management techniques you can use to handle inventory in the most efficient way possible.

Production Budget

Most manufacturers use the production budgeting formula below to make a production budget that indicates the ideal production volume based on a starting inventory, sales forecasts, production capacity and expected ending inventory levels.

Required Production = Sales Forecast Expected Units + Desired Ending Inventory – Beginning Inventory

Resource Plan

A successful production plan requires you to be familiar with the resource planning details of the manufacturing process, which is why you’ll need to make a resource plan that outlines what resources such as labor, raw materials, equipment and any other capital assets are available for production and when they’re scheduled to be utilized.

Production Cost Estimate

Once you’ve determined what the required level of production is and the resources that will be needed, you’ll need to estimate the cost of production . It’s important to ensure the production process will be profitable before creating a production schedule.

Production Schedule

As stated above, a production schedule is key to making sure your manufacturing team delivers products on time, but also guides efforts in other areas such as supply chain management and logistics management.

Production Control Plan

A production control plan should describe all the metrics, procedures, guidelines and tools that will be utilized to monitor how the results compare to the production schedule and resource management projections. This is something that should continually take place and be documented during the production process.

Types of Production Planning

Every operation is unique, and the same production plan isn’t right for everyone. To get the most from project planning, you decide which method is best for your manufacturing process. Here’s a quick intro to the different types of production planning.

The job method is often used when manufacturing a single product, for which a unique production plan is created. This production planning method is generally used in smaller-scale productions, but it can also be applied to larger manufacturing facilities. The job method is especially advantageous when a production order requires specific customizations.

Batch Production Method

Batch production consists of manufacturing goods in groups, instead of being produced individually or through continuous production . This method is useful when manufacturing products on a large scale.

Flow Method

The flow method is a demand-based manufacturing model that minimizes the production lead time by speeding up the production line. The manufacturing process starts based on work orders, and once it starts, it doesn’t stop until all finished goods are produced. This is called continuous production and it’s achieved by using machinery and little intervention to minimize waiting time.

Process Method

The process method is more or less what most people picture when they think about production—an assembly line. With the process method, there will generally be different types of machinery that complete separate tasks to put together the finished goods.

Mass Production Method

The mass production method primarily focuses on creating a continuous flow of identical products. It’s similar to the flow method, but at a much bigger scale, which cuts production costs. When uniformity is just as critical as efficiency, use “standardized processes” to guarantee all products look the same.

Production Planning Best Practices

No matter what product or service is being manufactured, there are many tried-and-true best practices to increase your operational efficiency . When creating a production plan, keep these two in mind.

Make Accurate Forecasts

When you don’t properly estimate the demand for your product or service, it’s impossible to create a detailed production plan. Demand planning is never static. Consider buying trends from previous years, changes in demographics, changes in resource availability and many other factors. These demand planning forecasts are the foundation of skillful production planning.

Know Your Capacity

Capacity planning means knowing the maximum capacity your operation can manage—the absolute most of a product or service it can offer during a period of time. This is the only way to anticipate how much of each resource you need to create X amount of products.

When you don’t know the production capacity, your production planning is like taking a shot in the dark.

Common Production Planning Mistakes

Stay vigilant of common missteps as you go through the production planning process. Here are three mistakes often made during production planning. Luckily, they can be prevented.

Not Expecting the Unexpected

This means having risk management strategies in place if things go awry. The goal is to never have to employ them, of course, but it’s better to have them and not need them. Production planning is incomplete if it doesn’t anticipate risks, issues and changes. When you plan for them, you’re ready to problem-solve if and when they happen.

Getting Stuck Behind the Desk

You should work with intelligent production planning tools, but that doesn’t mean you should only rely on enterprise resource planning software for production planning and not oversee resources and manufacturing operations in person. When production planning is only done from behind a screen, the result won’t be as informed as it could be. The best production planning is active and collaborative.

Neglecting Equipment

To get the most from your equipment, you need to take care of it. This means tracking usage and keeping up with regular maintenance. This looks different depending on the industry and product or service, but the principle is the same: continually take care of your equipment before it becomes a problem that slows down production.

Use ProjectManager for Production Planning and Scheduling

As the nature of manufacturing goods and services changes, you need modern tools to plan production and make schedules. ProjectManager is award-winning project management software that offers all the tools you need for excellent production planning and scheduling. With it, you can plan projects, create schedules, manage resources and track changes with one tool.

Plan With Gantt Charts

Manage your product manufacturing across a timeline with our Gantt chart view. With it, you can view your resources to help you track your cost of production to ensure you’re never overspending. You can then link any dependent tasks to avoid bottlenecks in your manufacturing.

Get a Bird’s-Eye View

To keep your production plan on track, you need a high-level view to pinpoint setbacks before or as they occur. Our real-time dashboard collects data and converts it into colorful graphs and charts that give you at-a-glance analytics.

Easily Measure and Report Your Progress

Any operation will have stakeholders who want to be kept in the loop. ProjectManager’s project status reports make it easy to share key data points. They can be generated in a single click, making it simple to generate them before important meetings.

Related Production Planning Content

The production planning process involves many different activities such as estimating the quantity of goods to be produced, the resources needed, the production schedule and much more. That’s why we’ve created dozens of blogs, guides and templates on production management topics. Here are some of them.

- Production vs. Manufacturing

- How to Make a Production Flow Chart for Manufacturing

- Best Production Scheduling Software Rankings

- How to Create a Master Production Schedule (MPS)

Manage every detail of your operation with ProjectManager’s powerful online project management tools. Our suite of tools is trusted by tens of thousands of teams, from NASA to Volvo, to aid them in the planning, scheduling, tracking and reporting on the progress and performance of their production plans. Our software lets you get out from behind your desk and make adjustments on the go. Try it for yourself for free for 30 days!

Deliver your projects on time and under budget

Start planning your projects.

What is production planning and how to do it? A comprehensive guide.

Production planning is crucial for efficient production. Let’s explore all about it and see how to handle it in ERP software.

Production planning is vital to fulfil orders on time. If you don’t know your stock levels, workstation availability, or job schedules, you won’t be keeping your customers happy.

Whether you’re a new manufacturer oiling your machinery for the first time or a seasoned manufacturer shipping thousands of items, production planning is a must. Similar to how scrums and monthly plans run operations smoothly, production plans ensure optimal usage of resources.

In this blog, let’s understand the basic terms around production planning, see how it’s done, look at common pitfalls to be aware of, see the types of production planning, some topics around production planning, and finally an example of handling production planning in ERPs.

1. Production planning basics

1.1 what is production planning.

Production planning is the planning and allocation of raw materials, workers, and workstations to fulfill manufacturing orders on time. In a make to order environment, manufacturing orders or work orders themselves are created after receiving customer orders. A company that follows make to stock style of manufacturing will create work orders on a timely basis depending on demands. Production plans are usually set by the production managers who supervise the shop floor. A good production plan makes the best use of available resources to deliver orders on time.

1.2 Why should you do production planning

Handling a few production orders in spreadsheets works but for large manufacturing shops, the complexity increases a lot. Production planning helps to plan the procurement of raw materials based on the quantity of finished products to be manufactured. It also affects inventory, cash flow, sales, and distribution.

2. How to do production planning

2.1 five tips to improve production planning.

These tips to keep your production plan on track and improve its efficiency

2.1.1 Forecasting demand

Before production planning, the first action to take is forecasting demands for your products. While this may not be accurate to the last digit, getting rough estimates rolling is important to allocate resources. Forecasting can be done based on factors like historical order data and market trends/demands. Drawing out proper forecasts helps planning the type and quantity of materials to be produced and also the planning of raw material procurement.

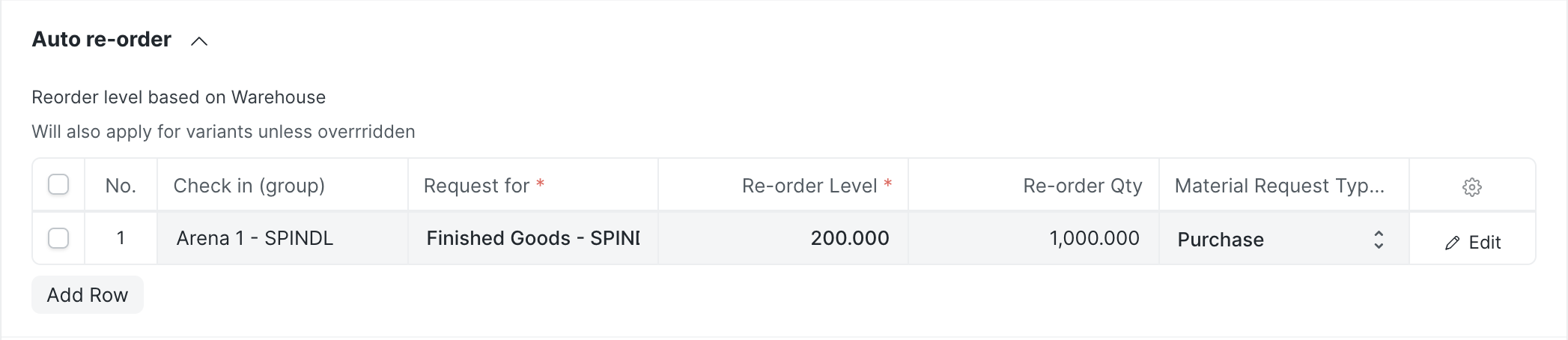

2.1.2 Control inventory

Both, inventory shortage and inventory surplus are undesirable states. You can’t proceed with production when there’s a shortage and you waste space and money when there’s a surplus. Efficiently controlling inventory involves reordering when current inventory dips below a certain level, calculating the lead times to order items with long lead times earlier, and factoring in storage conditions. A well-controlled raw material inventory helps run a smooth production line and outputs finished goods inventory on time.

2.1.3 Plan for everything and everyone

Often, when making production plans, some machine or some person is unaccounted for. The problem here is that that machine may go down or the worker may be on leave, or worse, working on something else. Hence, plan for every machine, raw material, workstation, warehouse, and employee.

2.1.4 Monitor

Once the production plan is final and work orders are handed out, the manufacturing process begins. At this point, things may go wrong, machines pause, or items may get misplaced. Constantly monitoring the factory floor with supervisors or with IoT devices ensures that all the pieces are moving as planned.

2.1.5 Adapt

Despite your best planning, things go wrong on the factory floor. Anything can happen from suppliers making late deliveries to workers falling sick to machines failing. It’s important to be flexible and adapt to these changes quickly so that the planned quantities can be delivered on time. Ideally, you should also plan for any such risks beforehand.

2.2 KPIs for production planning

A few key performance indicators to track in production planning are:

- Production cost : This is essentially the monetary cost involved in producing the item. Costs include raw materials, electricity, fuel, worker salaries, rent, etc.

- Capacity utilization rate : It’s the percentage of actual manufacturing output against the total possible manufacturing output. If many machines and workers are sitting idle, your capacity utilization is low. Ideally, you want it high but never full.

- Projected versus actual hours : When planning, you may allocate a certain number of hours for completion of the production plan. But, it may take longer due to delays from workers or unexpected tasks. This KPI gives you a picture of how much time it was supposed to take and how much it did.

- Employee utilization (productivity) : You want workers to be working properly during the punch in and punch out. Nobody wants to be a machine by working to the dot but working 4 hours out of 8 is also not reasonable.

- Takt time : Takt time is a lean manufacturing concept. It is the time taken to produce a single unit of item.

3. Production planning pitfalls and avoiding them

First, let us understand the pitfalls or things that could go wrong during production planning. These occur in areas from idle inventory storage to active workers.

3.1 Stockouts

What is it?

It’s the shortage of raw materials that can happen after fulfilling large orders or due to negligence.

How to avoid it?

By checking inventory reports regularly or better yet, setting up automatic reordering.

How to do it?

By setting automatic reordering like this:

3.2 Assigning work to workstation on downtime

Assigning operations to a workstation that was supposed to be on downtime. This causes confusion and the work doesn’t get done because there’s no machine available.

Get a view of which workstations are on downtime and assign only to available machines. (version 13)

By analyzing the downtime of different machines and assigning work appropriately:

3.3 Bottlenecks

These are roadblocks in the production line that halt the processing of materials midway. For example, if items are waiting at the painting stations to get painted, the painting station is a bottleneck since it’s stopping the items from going ahead.

Bottlenecks can happen anywhere in the production line. Scan all the machines and even check if there are enough workers to carry out tasks. Through planning and ensuring the availability of machines and resources is a good way to avoid bottlenecks.

Setting up regular maintenance activities helps by keeping machines running. Eliminating bottlenecks in the production depends a lot on having sufficient machinery, manpower, and a regular supply of raw materials.

3.4 Insufficient worker training

Some specialized machines need trained workers for operation. Hiring rookies running specialized machines result in work not getting done.

Interview candidates for skills and experience in operating similar machinery. Even after interviews, thorough training should be done to ensure that the worker is ready to use the machines in production.

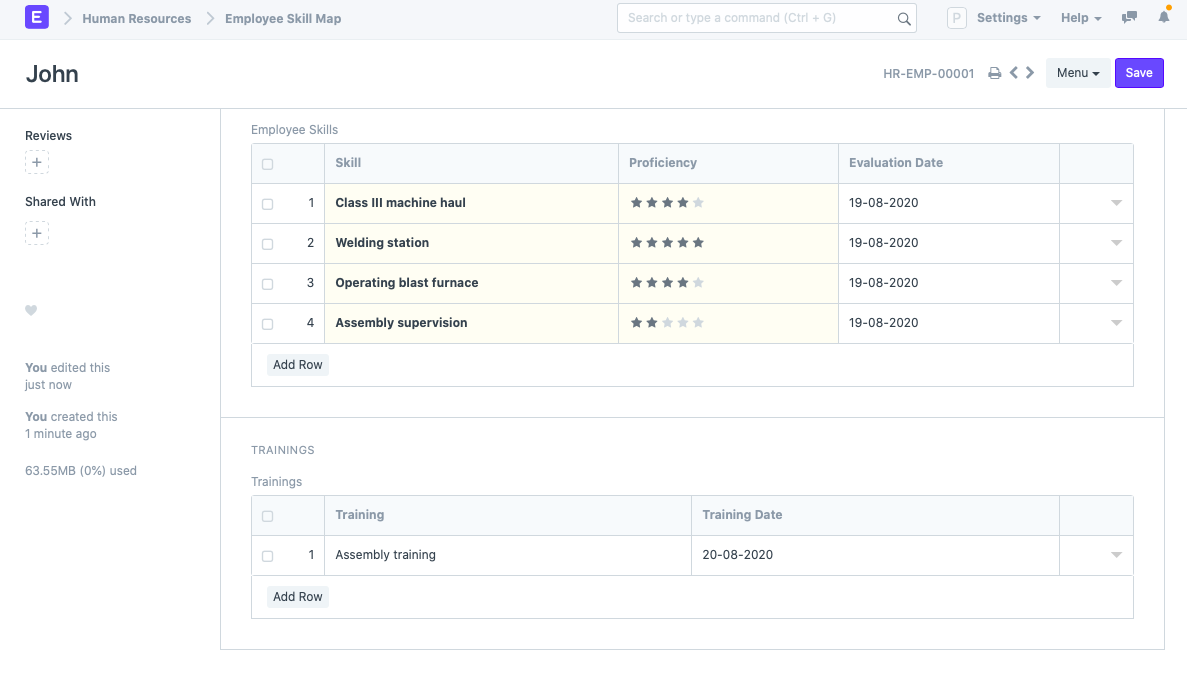

From the human resources module, first, test the employee’s skill proficiency. Then, set training events to enhance their skills. Updated employee skill maps help supervisors better allocate work to the right people and help the ones that are lagging.

4. Types of production planning

The different types of production planning are based on the manufacturing process followed in the factory. A single organization can deal with different types of manufacturing depending on the goods produced.

When items are manufactured in batches with unique batch numbers allotted to each batch. Production planning in batches helps run machinery in a well-planned manner as the next step is planned and the machines are allocated accordingly.

This type of production planning is common in job shops where custom material processing requirements are carried out. Each production plan will most likely be different from the last with the use of different materials, machinery, and operations on the materials.

In flow method, materials are processed smoothly from one machine to the next with very little human intervention. Any waiting time or bottlenecks are removed so that the materials ‘flow’ continuously till they become finished goods. Standardized work and quality control are essential to ensure consistent quality when producing items with the flow method.

5. Topics around production planning

5.1 production planning and control.

Production planning is about planning resources for delivering products and production control is about controlling the production system to achieve targets optimally. Production control has more to do with monitoring the production line and taking corrective action where things are not moving as planned.

‘Production planning and control’ is simply applying both these concepts to get an efficient production line.

Let’s understand the benefits of using both these methods together:

- Better organization for on-time delivery to customers

- Optimum resource utilization

- Less investment in inventory

- Avoid resource wastage

- Increased efficiency, hence reduced costs

- Improved quality by catching and reducing defects

Now let’s look at these topics individually to further distinguish between them.

5.1.1 Production planning

The steps involved in production planning are:

- Planning : This involves planning shop floor resources to deliver finished goods on time.

- Routing : The exact route/path or set of operations the materials go through is known as a routing. Finding optimum routes that reduce wastage and promote continuous flow is a part of production planning. Finding better routings is about using workstations, machines, and workers in different orders without affecting the product to deliver the items faster.

- Scheduling : The machines, activities, and workers are scheduled to do tasks that are a part of the production plan. Scheduling well helps in delivering the finished products on time.

- Loading : Loading here refers to overloading the production line to see how much it can handle. By loading each point, the last bits of efficiency can be squeezed to get the maximum value.

5.1.2 Production control

The steps involved in production control are:

- Dispatching : After the production plan is ready it’s time to implement it by dispatching items in and out of the production line. Different operations and the corresponding workstations are managed to dispatch items to them. The time to complete each activity or ‘job’ is recorded.

- Followup : After issuing a plan, bottlenecks and other problems may arise. Follow-ups are done by supervisors to eliminate any bottlenecks and ensure that things are going according to plan.

- Inspection : Routine inspections are done during production to verify that the materials are being processed correctly. Note that this is different from quality inspections which are done after the product is finished.

- Correction : The results from other steps in production control are reviewed and corrections are made where necessary. This includes the routings, scheduling work, and even conversations with workers who are taking those long breaks.

5.2 Production planning and inventory control

An indispensable part of manufacturing is managing your inventory. Controlling inventory is an essential part of production planning. Proper inventory control involves ensuring an adequate supply of raw materials which results in the timely delivery of products. It also minimizes the overstocking of finished products. Maintaining both—proper inventory levels and accurate data—helps in good production planning.

5.3 Production planning vs production scheduling

Production planning is about planning the number of resources needed to finish multiple manufacturing orders. Production scheduling is about timing the activities, machines, and workers right to run the production process. The work and workloads are optimized in production scheduling. There are two ways production scheduling is performed:

- Forward scheduling : Say, if resources are available today, plan from today till the order due date.

- Backward scheduling : If the availability date of resources is not certain, plan from the due date backward to a number of days.

Production scheduling levels the inventory, labor, and helps in estimating delivery dates accurately.

6. Production planning in ERP software

A production plan can be created and managed easily by using ERP software. You’d need the items, bill of materials, routings, customer orders, and material requests ready before creating a production plan.

6.1 Creating the production plan

Once you have the prerequisite records ready, it’s time to create the production plan. Let’s follow through step by step.

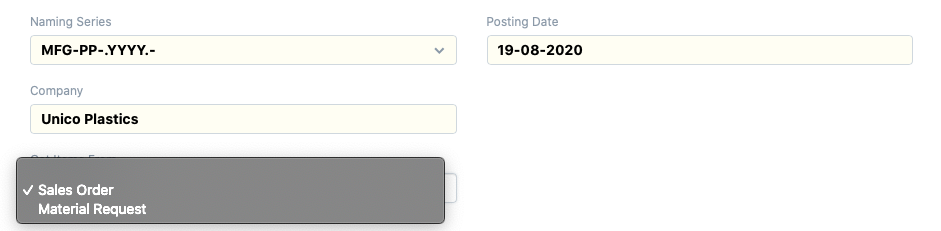

If the items to produce have been requested via a customer order or material requisitions, they can be fetched into the production plan.

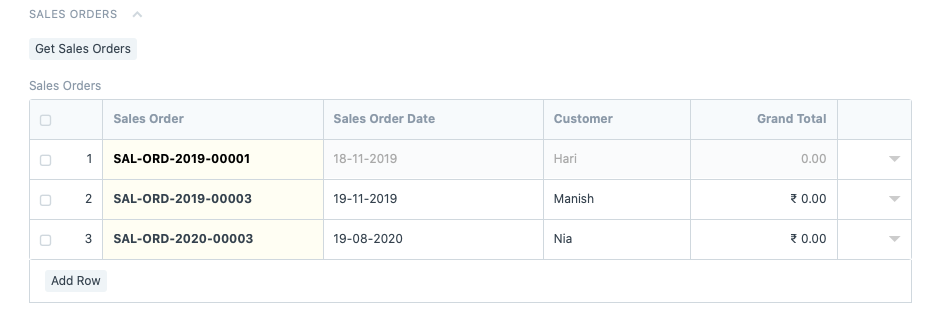

By clicking on ‘Get Sales Orders’, either multiple orders or multiple requests can be fetched here, like this:

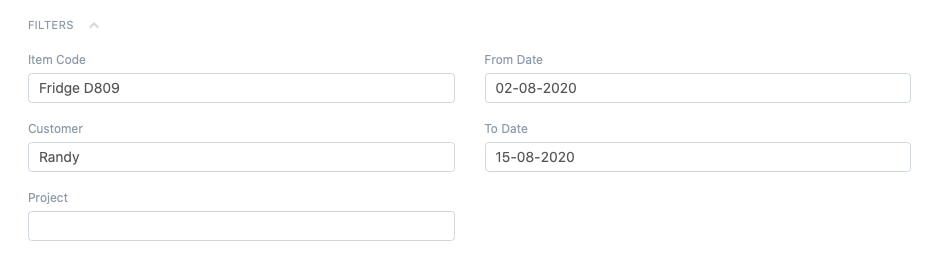

If you have a ton of orders or requests, set filters to narrow down your search like this:

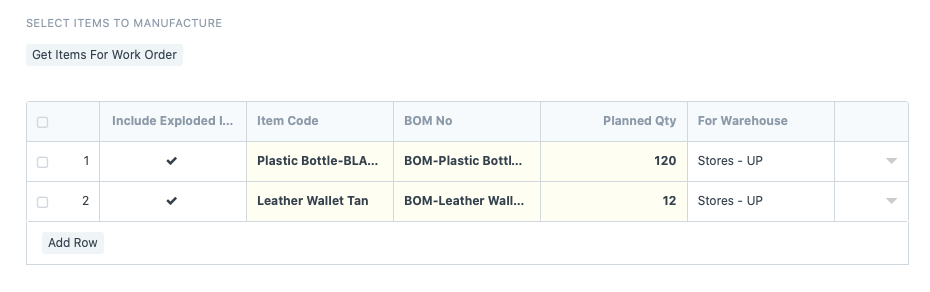

Now, by clicking on ‘Get Items for Work Order’, the items to be manufactured using the current production plan will be fetched. The quantities can be increased in case you want to account for SKUs. It’s a good idea to keep extra inventory for items that take a very long time to manufacture but have predictable, fast demands.

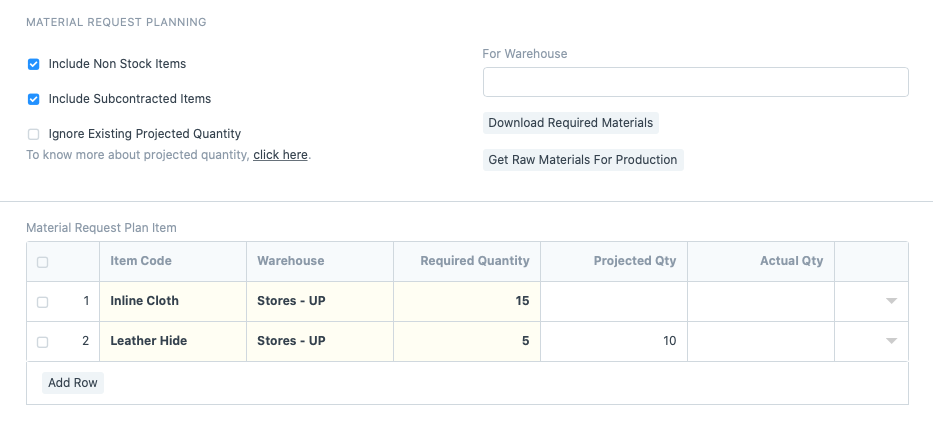

Now that you know what items to manufacture since the bill of materials has been fetched, it’s time to plan for the raw materials. Clicking on ‘Get Raw Materials for Production’ will fetch all the raw materials and sub-assemblies required for manufacturing. If the inventory levels are present in the warehouses, they’ll not be fetched here. Click on ‘Download Required Materials’ to download the raw material list as a spreadsheet, send it to others or print it.

Some options to note here are:

- Including non-stock items in case you want to account for some external items that you don’t store in your inventory but will be used in production.

- Some subassemblies may be subcontracted, you can choose to include or exclude them in your plan. The choice here depends on whether the subcontracting is for operations or assembly among other factors.

- Projected quantity will show the inventory levels that should be produced based on demands and requests. If you want to ignore this number and produce quantities that you see fit, go ahead and tick the ‘Ignore Existing Projected Quantity’ checkbox.

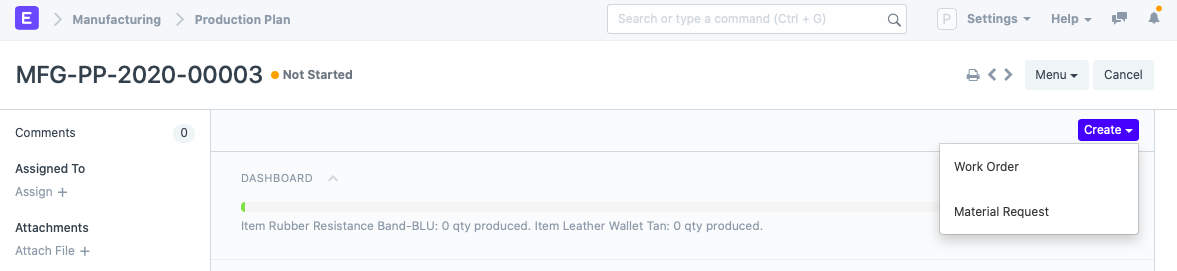

- Finally, you submit and start with the production plan. Then, from the production plan work orders can be created. One work order for each BOM will be created if you click on ‘Create > Work Order’.

In the work order, the quantity to be produced can be changed depending on whether you want to produce some quantities later. Work orders are used by shop floor supervisors.

From the work orders, job cards are created to record the operations on raw materials. The jobs/operations are done at different workstations/machines.

Once the ‘jobs’ are done on the materials and items are processed, the work order is complete.

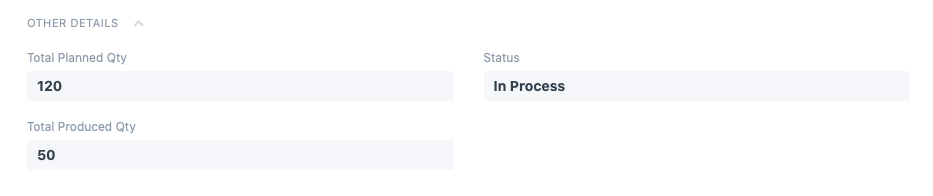

Now, depending on the quantity of items produced, the following details can be seen in the last section of the production plan:

6.2 Scheduling the plan

Creating a production plan is one part of the planning process, the other is scheduling different resources to the production plan. Factors like machine downtime, workstation capacity, and availability of raw materials are taken into consideration when scheduling.

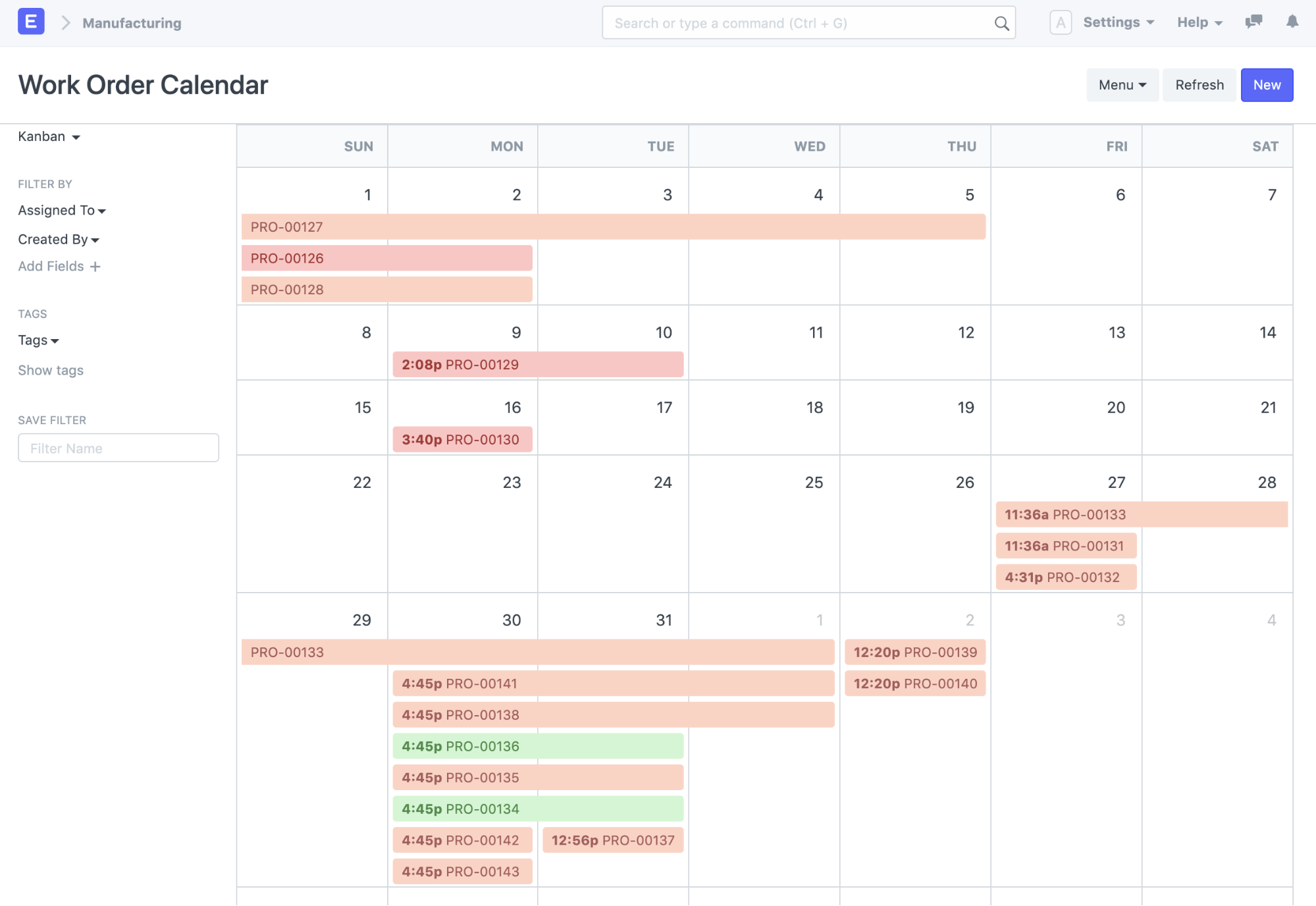

In ERPNext, capacity planning is enabled by default. If you go to the calendar from the work order list, you can see the workstations for which materials are transferred and work has started (orange), neither materials are transferred nor work has started (red), and the ones that have been completed (green).

6.3 Role of project management in production planning

In larger organizations with multiple orders or when you get a large project from a client to produce hundreds of different items, project management comes handy. By using a project in ERPNext, you can create multiple work orders against it to track them all from one place.

That's it. Production planning is done easily with the right tools. By allocating resources carefully, planning for inventory, and avoiding mistakes, you can deliver you orders on time.

First, we introduced what a production plan is and discussed its importance. Then, we talked about the important things to note before creating a production plan and talked about the common mistakes to avoid when planning. Further, we talked about the types of production plans and the role of software in production planning.

For a monthly digest of such blogs and more updates, subscribe to our newsletter .

- Production planning

- Methods of production

- Scheduling (production processes)

ERPNext documentation

- Production Plan

- Capacity Planning

- Operations: Methods of Production (Overview) | Business | tutor2u

- Production plan: Top tips for improving your operations

- Grace college production planning

Prasad Ramesh

Marketing at Frappe.

Thank you very much for your informative info on production planning as I really need to use as guidance for my job as production planner

We are extremely impressed with this article because it contains a lot of great information. We, at MGH Distributors, are a part of the Import and distribution business. Our food products include Candies, cakes, cooking oil, beverages, jelly products, cookies and many more. The FMCG range brings to you world-class razors, blades, bar soaps. Visit our website to know more

Thank you for this very good overview on production in ERPNext.

- 888-375-2368

Production Planning: How to Create The Ideal Production Plan

Sign up to receive updates

Supply chains have grown more complex over time. There’s no end to all of the different challenges that warehouse managers face from manufacturing in-house and maintaining multiple locations.

Production planning is one beneficial way of getting ahead of the rush and having a good understanding of your supply chain management and strength.

Waiting for a rush of orders to disrupt your warehouse flow should never be an option. Use these production planning tips to improve your warehouse planning.

How Does Production Planning Work?

Production planning is the process of efficiently coordinating resources, activities, and processes in manufacturing to meet customer demand. It begins with demand forecasting and aligns production with sales plans through sales and operations planning (S&OP). The plan considers resource availability, schedules production tasks, manages inventory, and incorporates quality control measures. Capacity planning ensures production aligns with manufacturing capabilities, while risk management addresses potential disruptions. Continuous monitoring allows for real-time adjustments, and the process fosters continuous improvement. Production planning aims to optimize production efficiency, cost-effectiveness, and customer satisfaction, making it a vital aspect of supply chain management.

Benefits of Good Production Planning

There are a few key benefits that come with good production planning.

- Improved customer service : When you can accurately forecast production needs, you can better meet customer demand and avoid stockouts.

- Increased production efficiency : A well-planned master production schedule prevents bottlenecks and allows for a smooth workflow through the warehouse.

- Reduced production costs : A good production planner will optimize the production process, reducing waste and ensuring that resources are used in the most efficient way possible.

Key Methods of Productions Planning

One of the most important production planning tips is to communicate your production plan to all parties involved.

Your production planning team should work closely with purchasing, operations, quality contro l, and sales teams to create an effective production schedule.

Ongoing communication about changes or disruptions within the supply chain is critical for production planning.

Specific to manufacturing a single product, the job method production planning is a production-oriented plan that uses routings to define the sequence of operations and tasks required to manufacture a product.

The job method production plan starts with the finished goods and works backward, defining each operation and task needed to produce the final product.

This type of production planning is common in batch and repetitive manufacturing environments with single products and smaller warehouses.

Batch Production Method

Batch production refers to individual products produced in batches or groups specific to a single product. In this type of production, products are made to order and typically in varying quantities.

Operations within a batch production environment will generally have some common characteristics:

- The same product is produced over and over again

- Operations are usually done sequentially

- There is often a lot of setup time required between each batch

Flow Method

This method is based on the continuous production of large quantities of one or more products. Flow production refers to the continual production flow and uses assembly lines, conveyors, and other automation tools. Systems are closely monitored using an OEE calculator and similar tools to ensure operations run efficiently.

Flow production typically requires less setup time than batch production methods because there is no need for multiple setups between different production runs.

Process Method

The production planning process is closely aligned with the production scheduling of jobs. Production planners determine which steps come after, how they should be processed, and the production rate.

Production planners work to determine when each step will be processed and how many staff are needed for each step in production scheduling.

This method is common in businesses with a high mix of products and frequent changes to the production schedule.

Mass Production Method

A production planning approach that uses standard routings to produce products in large quantities is known as mass production.

This type of production planning is common in businesses with low product variety and high demand.

In mass production, the goal is to produce as many product units as possible while maintaining quality standards.

How to Choose the Best Production Plan

Most obviously, the type of product you’re producing and the most appropriate production process will impact the production planning method you choose.

Here are some factors to consider as you determine what production plan is best for you.

The Level of Demand

One key question to ask yourself when choosing the right production plan is whether or not your products experience a high volume of orders. Flow production may be the best option to maintain production levels if products are constantly in demand.

The Number of SKUs That Will be Produced

The more unique products you produce, the less likely job or batch production planning will be effective. In these cases, process or mass production methods are better suited for producing large quantities of products.

How Many Steps to Production Are There?

Another important factor to consider when choosing a production plan is whether or not there are multiple production steps required for each product. If so, you’ll want to know if the production processes can be performed simultaneously or sequentially. The decision on how to produce your SKUs will depend heavily on this information.

The Level of Variability in the Production Process

If production processes are highly variable, it can be difficult to use batch production planning. In this case, flow production is often a more effective option because it allows for greater flexibility and faster changes to production schedules.

The Skill Level of Your Workforce

If your workforce has limited production skills or production is performed by untrained workers, your planning will be different than if you’re working with a skilled labor force. Many companies find that process production planning is a good option because it allows for better control of production lines and minimizes the need for highly skilled labor to perform complex steps.

Steps to Creating Your Production Plan

Now that you have a better understanding of the different production planning methods and how you’ll choose the right method for you, it’s time to create your own production plan.

The following steps will help you develop a production plan that meets the specific needs of your business.

1) Gather Estimates and Forecasts of Product Demands

The first step in production planning is to gather data on estimated product demand. This information can come from sales forecasts, customer surveys, or other market research sources.

Once you have an idea of the level of demand for your products, you can begin to plan production around these estimates.

2) Assess Current Inventory Levels

Inventory data is also essential for production planning. You need to know what inventory levels are currently available and how much stock you’ll need to produce your estimated product demand.

This information will help you determine the production schedule and identify any potential bottlenecks in production.

It’s important to note that not all products can be produced in large quantities. If you have products only produced in small batches, production planning will need to take this into account.

3) Plan and Determine Needed Resources

The next production planning step is determining production capacity, overall production costs, and the required resources. This includes equipment, raw materials, and labor. Once you have an idea of what’s needed, you can develop a production plan.

Many factors will impact production capacity, including the number of products being produced and the level of demand.

4) Monitor Production Levels and Plan Release Dates

Monitoring production levels and planning release dates is the next step in your process. This will ensure production is on track and running smoothly. You should also set goals and track key performance metrics (KPIs) for production, such as the number of products to be completed per day or week.

These production planning steps can help your business run more efficiently and ensure products are delivered to customers on time.

5) Make Adjustments to Improve Production for the Future

Finally, production planning should include an evaluation of production processes and assessing how production was managed during the process.

This information can be used to make production methods or equipment changes for future product runs. This helps you avoid issues that occurred in previous production runs, saving time and money down the road.

Get the Help You Need With a Quality Warehouse Management System

At Extensiv Warehouse Manager, we offer topShelf –a premium warehouse management tool that can help you keep your business on track.

From employee tracking to inventory control and stocking, you’ll get all the help you need to ensure that your business runs smoothly and your team keeps fulfilling production orders at a record pace.

Choose Extensiv Warehouse Manager for your inventory management needs , and you’ll get a team of experts to guide you and get your new inventory management system up and running.

Product Planning FAQs

An Enterprise Resource Planning (ERP) system plays a significant role in production planning and scheduling by providing a comprehensive and integrated platform to manage various aspects of manufacturing operations. An ERP system streamlines production planning by integrating various aspects of the manufacturing process, providing visibility, and enabling efficient utilization of available resources. It leads to improved production efficiency, reduced lead times, on-time delivery, and enhanced production control.